Ofey wrote:I am out of my depth here but would like to know :

Why would exhaust and mid pipe manufacturers quote in OD (or Outer Diameter)?

I agree it sounds wrong to quote an outside diameter rather than the inside .... since the inside diameter is the "Actual & Operative Diameter" which governs / determines and influences exhaust gas flow.

However, Think of it this way: The outside diameter is always going to be constant/correct as measured.

Explained:

If you measure a pipe as 2 1/4" outside .... then it is correctly stated as 2 1/4" outside .... irregardless of wall thickness.

If you measure a pipe as 2 1/4" inside ..... then the outside diameter will need to be re-calculated by adding the wall thickness of the pipe (generally 1/16" x 2) = 2 3/8".

You could argue that if all manufacturers agreed and adhered to a worldwide standard .... then it would be OK to use the inside diameter as the "Identifying Size"

Not Really .....

Firstly: Exhaust Pipe sizes are standardized in Easy 1/4" increments.

Secondly: Exhaust Pipe Manufacturers make exhaust pipe from many different metals such as Mild Steel, Iron, Cast Steel, Stainless Steel, Titanium etc etc.

Since some metals are either weaker or stronger than others .... the thickness's (gauge) needs to be considered and applied in the manufacturing process in order to achieve the equal/desired Tensile strength suitable for the exhaust application.

A Common Automotive Exhaust Scenario:

A 2 1/4" (outside) Mild Steel Pipe with a wall thickness of 16 gauge (1.65mm) (weaker metal --- is thicker)

A 2 1/4" (outside) Stainless Steel with a wall thickness of 16 gauge (1.59mm) (stronger metal --- can be thinner)

Difference = .06mm x 2 for both sides of the pipe = .12mm

You can clearly see that using the "Inside" pipe size & applying this minor "

.mm" difference to all exhaust pipe "Outside" sizes would complicate and confuse the entire "Identity Size" Issue, and the Easy 1/4" Standard could not apply.

Furthermore: Size complications would occur when Pipe/Component Connection situations are encountered such as .... one pipe inside another or when fitting the mid-pipe into a muffler, reducer, y-piece or exhaust tip.

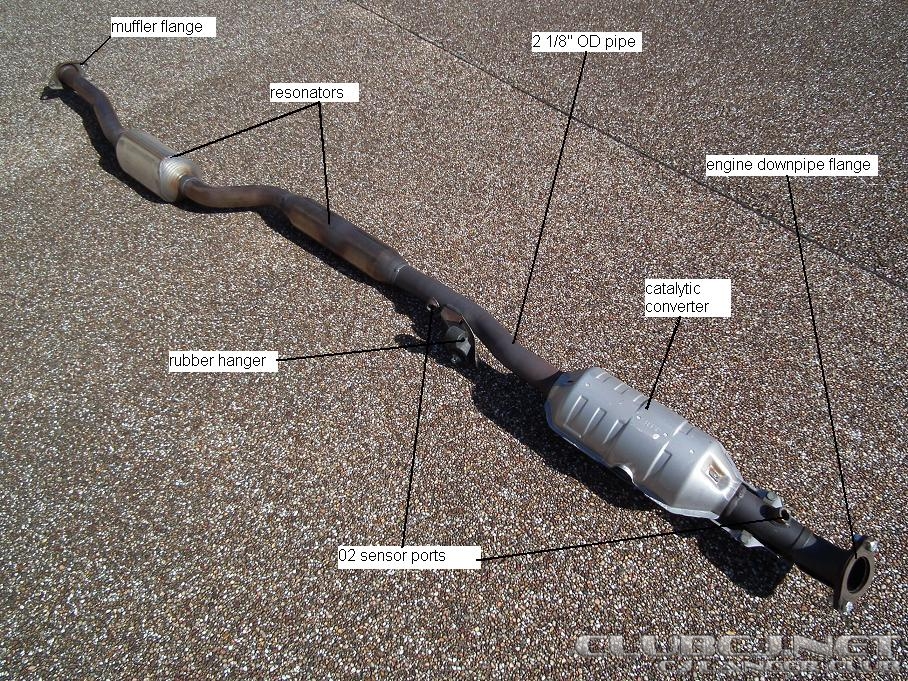

Note to Remember: Although Exhaust Pipe is Manufactured and Measured at the Outside Diameter ....

All and/or Most other Exhaust Components such as Mufflers, Cats, Reducers/Extenders, Collectors, Y-Pieces are made and measured on the inside diameter,

since they all and/or in most cases fit over the outside of Exhaust Pipe.

Conclusion ... as per the Automotive Exhaust Industry Standard.

It's far more Simple, Easy, Less Mistaking & Accurate to use the "Outside" size as the "Identifying Size" .....

since the wall thickness (gauge) of the pipe "does not" have any influence over the outside size .... and Inside size for Exhaust Components.

I hope this clears-up and explains why the Automotive Exhaust Industry designates the:

"Outside Dimension for Exhaust Pipe"

"Inside Dimension for Components"

as the Correct Method for Size Identity.

Sam .....

Merlinised AspiRe 2.4L

Merlinised AspiRe 2.4L